Diamond Cut Alloy Repair

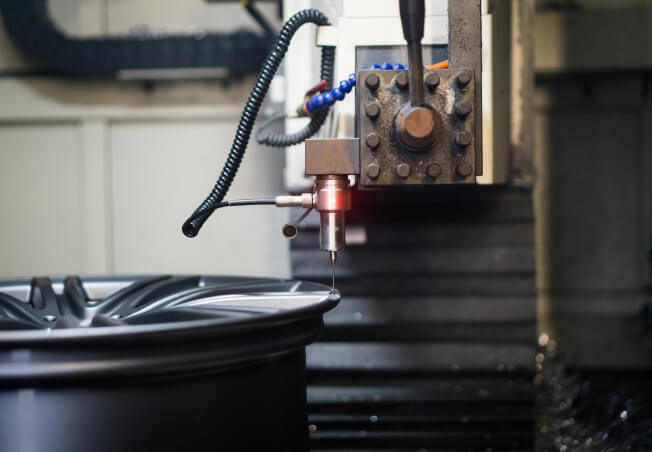

Alloy wheel diamond cutting is a specialised service that involves restoring the finish of diamond cut alloy wheels. Diamond cut alloys are known for their shiny and reflective surface that catches light and sparkles, but they are also more susceptible to damage from road debris and harsh weather conditions. This is where diamond cut alloy wheel repair comes in.